|

The Argo Gold Mine and Mill in Colorado

Photo by Dustin Moore |

Whatever you may say about gold it sure attracts people's attention in a hurry so it was with the

Colorado Gold Rush. The gold miners were egged on by the cries of, “

Pike’s Peak or bust.” Rumors of gold date back to 1807 when the Mountain Man Zebulon Pike heard rumors of gold in the

South Platte River. By 1859 rich deposits of gold were discovered in the mountains west of

Denver when the miners abandoned the plains. The first placer mines were around

Denver sparking the first Goldrush in 1858.

Gold was found in the following plains counties Adams, Arapahoe, Douglas,

Denver, Elbert

and Jefferson. Small amount of placer gold is still produced from Sand & Gravel banks around

Denver as a byproduct of gravel washing operations by the aggregate producers.

The district around

Central City and Blackhawk was another important gold mining district that produced enough gold to bankroll the modern city of

Denver with several hardrock mines being in the district.

At one time the author had dibs on part of the

Bates - Hunter mine in Blackhawk. This is officially called the

Central City – Idaho Springs District.

|

The Teller House in Central City Colorado. Central City was the site of several goldmines during the 19th Century.

Photo by Hustvedt |

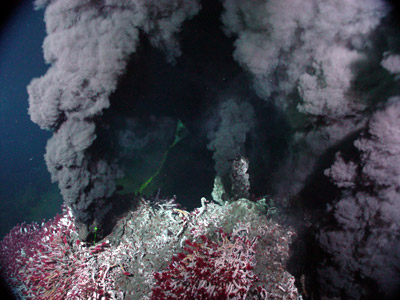

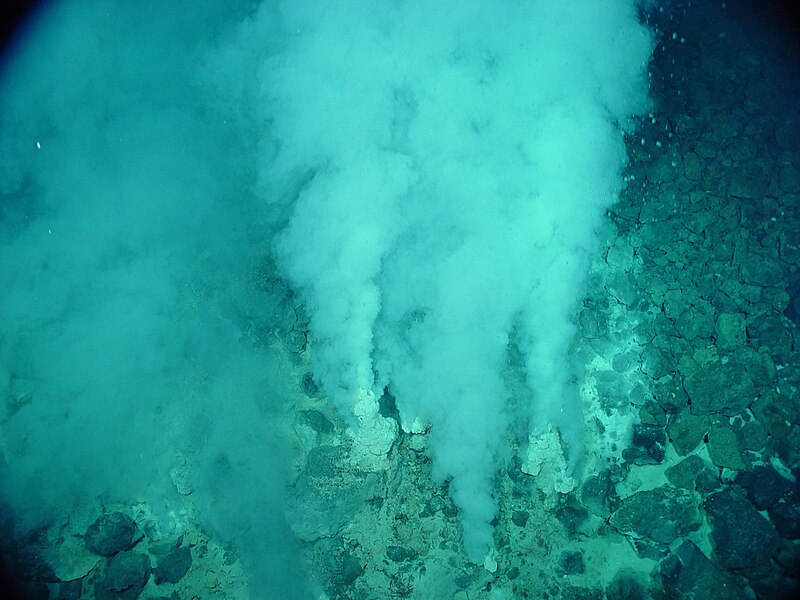

Gold was originally discovered in this area on January 5, 1859, by a former California prospector named George A. Johnson during the Pike's Peak gold rush. He made his discovery at Chicago Creek where it empties into Clear Creek; this marked the first significant Gold strike that was made in Colorado. Jackson who originally came from Missouri was able to conceal his strike for several months until he paid for some supplies with gold dust then the word was out. What had attracted Jackson in the first place were the large number of hot springs that belched columns of steam into the air. Jackson's discovery eventually led to a gold rush.

The presence of hot springs in the area is an indication that hydrothermal water sent shed themselves of their gold content into the surrounding rocks. The same hot springs gave the settlement a new name that was to be known as Idaho Springs. On May 5, 1859 another miner named John Gregory discovered a gold bearing vein but was later called the Gregory Lode between Black Hawk and Central City that was called Gregory Gulch. Within two months of this discovery several other gold bearing veins were also unearthed. These discoveries gave rise to the establishment of other mining towns in the area including Nevadaville and Russell Gulch.

|

| This is Pike's Peak that gave rise to the cries of Pike's Peak or Bust during the Colorado Gold Rush |

For a few years hardrock mining prevailed in the district until the miners exhausted the free milling gold that was prevalent in the shallower parts of the deposits. This Friday of gold or worked fine for the amalgamation process, but the miners could not recover any gold once they reached the sulfide ore at a deeper depth.

It wasn't until the invention of an effective smelter for the sulfide ore by Nathaniel P. Hill in 1868. This was an achievement that allowed hard rock mining to continue in the district where several other smelters were also built. It is estimated that by 1959 this district produced about 6,300,000 troy ounces of gold mainly from sulfide veins that were found in gneiss and granodiorite.

The early miners made their discoveries at the northeast end of the

Colorado Mineral Belt, but it wasn't too long before they started heading southwest across the mountains from Idaho Springs the miners traced the Colorado mineral belt west along Clear Creek, then over the mountain passes to South Park and from there to head waters of the Blue River.

This was the

Breckenridge district where the miners first discovered gold in the 1880s, By following the placer gold to its sources at the miners discovered that were veins in the hills containing gold. The miners even recovered some placer gold from the gravel benches to the north of the

Blue River. Although gold production Peter now during the late 1800s, but was revived by gold dredging in 1908 along the

Blue River. During its lifetime the Breckenridge district produced about 1 million troy ounces of gold. Today the gold mines around Breckenridge are all closed, but there are a few that remain open for tourists.

As early as 1859 prospectors had already found rich placer deposits on the west side of South Park in the valleys on the east side of the Mosquito Range in the principle districts of Fairplay and Alma.

These deposits were located at the headwaters of the

South Platte River with others in the Tarryall District alongside Tarryall Creek. Later they found lode gold deposits in the mountains above

Alma.

Some of these deposits were worked with floating dredges until 1952.

These gold miners left behind them the gravel ridges seen today. It has been estimated that production from these operations recovered about 67,000 troy ounces of gold. Altogether the

Alma-Fairplay district produced about 1.55 million troy ounces of gold with over two=thirds coming from lode deposits.

The discovery of placer gold at Oro City in 1860 opened the pages on the colorful history of the Leadville District. The placer deposits were exhausted within four years, but the discovery of lode gold in 1868 that later lead to the discovery of large silver deposits in 1877. It was also in 1877 that the city of Leadville was founded.

The gold and silver deposits at

Leadville were deposited in a paleo-karst environment where the rich ores were deposited in ancient river valleys that were later covered by volcanic deposits. The ore here acted as a replacement of limestone that is a common association for gold.

The ore was in the form of lead/silver sulfides with gold being produced as a byproduct.

It has been estimated that there were about 3.2 million troy ounces of gold produced from the Leadville District.

In 1870 gold was discovered by prospectors along the Wrightman Fork of the Alamosa River and a year later they found lode gold in veins where full scale production commenced in 1875 once they had build a mill. In this district gold production continued until 1906, but became sporadic after that until all production ceased in 1990. There were about 520,000 troy ounces produced in the life of this district.

At the southwest end of the

Colorado gold belt gold is found in

Telluride District where the gold is associated with several Tertiary volcanic calderas including the remains of the largest eruption ever discovered “

La Garita.” Here the deposits are found associated with

intrusives in the older sedimentary rocks as well as chimneys and veins in the volcanic rocks themselves. It is estimated that this district has produced about 6.8 million troy ounces of gold while it was productive. The same district also produced sizable amounts of silver, lead and copper during the same period.

The

Cripple Creek district has produced the most gold in

Colorado was not discovered until 1891.

After the discovery the towns of

Cripple Creek and Victor were settled to take care of the needs of the mines as well as the miners. Altogether this district has produced more then 21 million troy ounces of gold.

The Cripple Creek and Victor Gold Mining Co. was formed in 1979 with the idea of starting gold production in the district by working mine tailings from the old mines. In the period when they were active from 1979 to 1986 they produced around 150,000 troy ounces of gold.

In an exclusive interview with Jim Burnell of the Colorado Geological survey it was revealed that there are several hard rock deposits of gold that are ramping-up to resume production. There has also been a considerable amount of activity from the small scale miners that don’t have to report their findings to the state. According to Mr. Burnell there have been several exploration companies that have expressed an interest in Colorado gold, but for proprietary reasons they don’t want to have their names revealed.

To a limited extent gold mining is still going on in a large scale in Colorado, but the difficulties in permitting a large scale mine today make it extremely difficult to open a new mine. Several mining companies have tried opening some of the older mines that are grandfathered.